Creative Solutions

MODELMAKING

I spent the first twenty- five years of my working life as a full- time model maker and lived through the transition from traditional hand work to computer aided design and rapid prototyping.

A good knowledge of the old techniques is very useful, because there are still many instances where they can do the job better. A good example of this is when I create the free form shapes of the bodywork for a classic car, when only perhaps only a few photographs of the original exist. It is easier to make a scale model of the subject by hand and continuously refine the forms until they match up with the photograph. The finished model is then 3D scanned and digitised into the computer environment This model can then be manipulated and the ash frame can be designed. Using this data, the individual parts are then produced in house on a CNC machine.

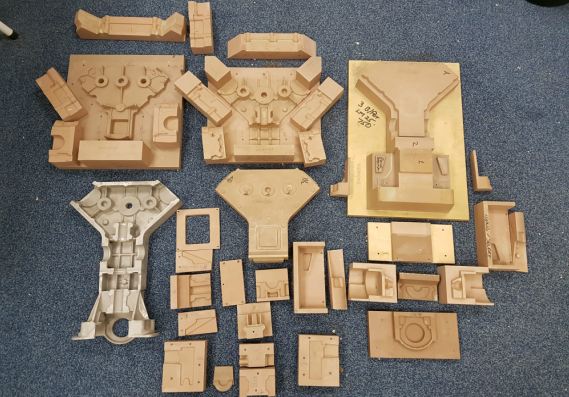

PATTERNMAKING

When reproduction of a rare classic car, many unobtainable castings are often needed and 3D computer modelling and CNC machining has made this a lot more viable. Draft analysis, contraction rates and core boxes can be designed and proven before the parts are machined.

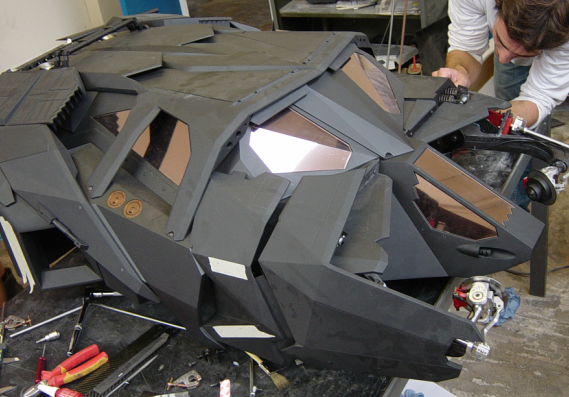

FILM MODELS / PROPS

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Mauris sagittis cursus magna, vel malesuada nisi feugiat nec. Praesent condimentum venenatis sodales. Nam metus lectus, condimentum sed urna ut, bibendum vulputate nunc. Integer elementum porta cursus.

3D PRINTING

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Mauris sagittis cursus magna, vel malesuada nisi feugiat nec. Praesent condimentum venenatis sodales. Nam metus lectus, condimentum sed urna ut, bibendum vulputate nunc. Integer elementum porta cursus.

BESPOKE PARTS

My model making background has given me a very broad knowledge of the science of things and has enabled me to design and produce a very diverse range of objects to the very highest quality.

BODY DESIGN / CONSTRUCTION

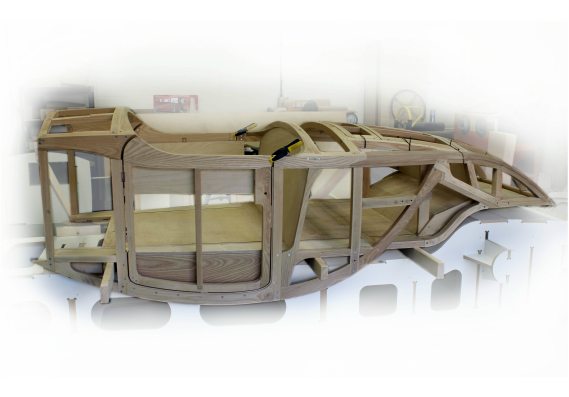

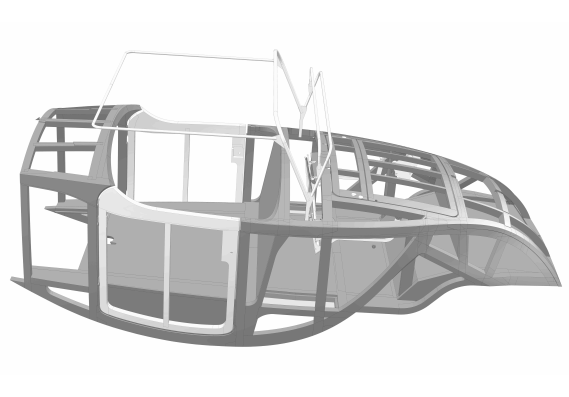

ASH FRAMING

I have developed a novel method of building ash frames for vintage cars that uses modern manufacturing techniques to build complex forms with very high accuracy and symmetry.The structure is designed in a computer environment from scanned data and then machined on a CNC machine.

SCULPTURE

I recently set myself the challenge of trying to capture the likeness of Ettore Bugatti (1881-1947).

I was quite pleased with the result and have produced a numbered run of twenty editions of them in bronze, using the lost wax process.

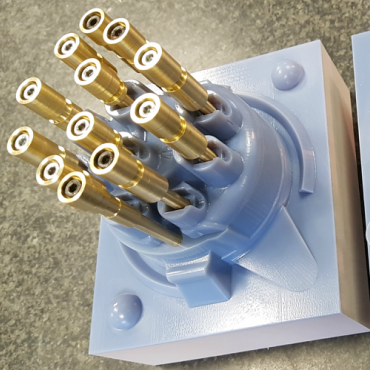

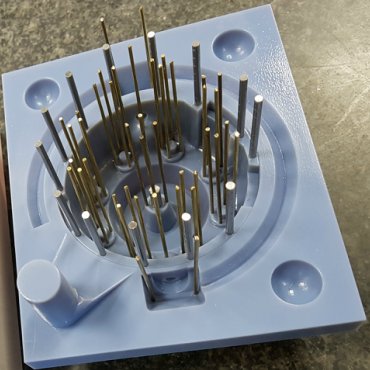

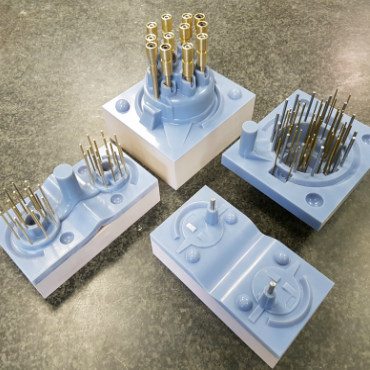

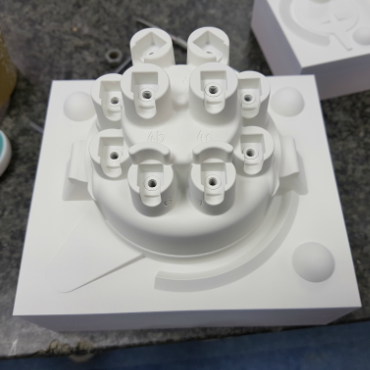

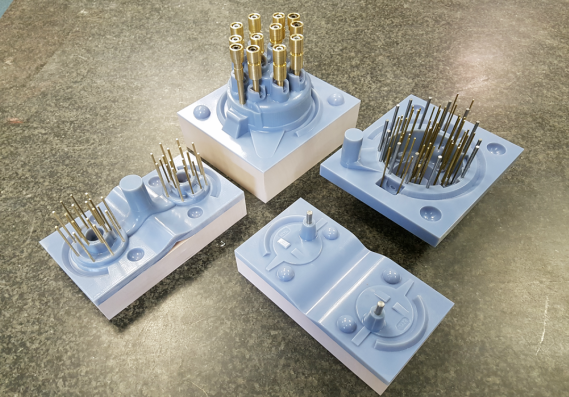

REPRODUCTION DISTRIBUTOR CAPS

Nearly twenty years ago I was asked if I could make reproduction magneto caps for the Bugatti Type 35 and after much trial and error I succeeded. Many of these cars are approaching one hundred years old and replacement components such as distributor caps and rotor arms are now unobtainable. Over the years, my process has advanced enormously to a point where I can manufacture almost unbreakable caps with three times the dielectric strength of the originals, for any car. It is a labour-intensive process, but in many instances, it is the only solution to an age-old problem.